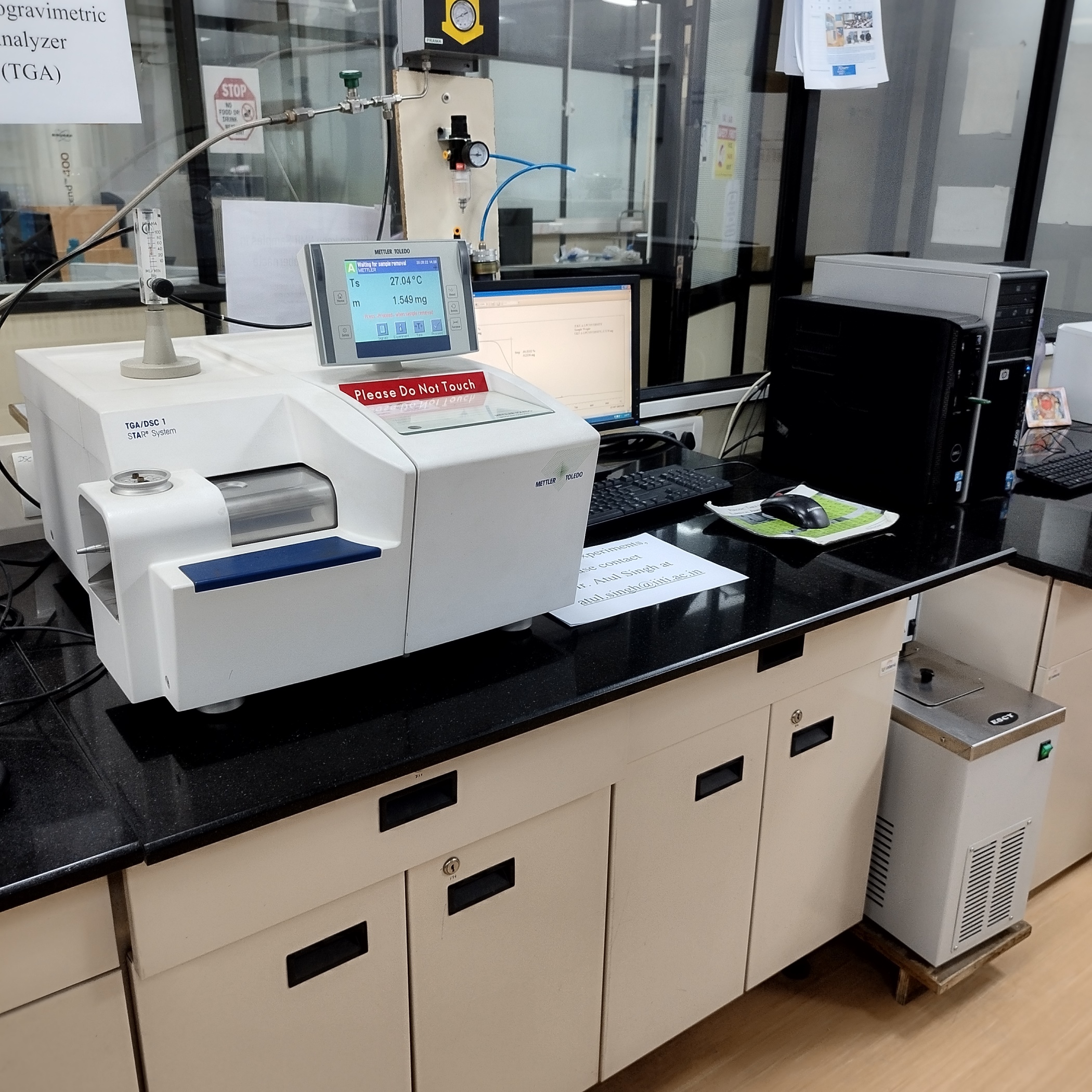

Model

METTLER TOLEDO TGA/DSC 1 STARe System

Features

Thermogravimetry (TGA) is a technique that measures the change in weight of a sample as it is heated, cooled, or held at a constant temperature. Its main use is to characterize materials with regard to their composition. Application areas include plastics, elastomers and thermosets, mineral compounds, and ceramics as well as a wide range of analyses in the chemical and pharmaceutical industries.

Applications

- In TGA the weight loss or gain is measured as a function of temperature or time.

- The TGA curve appears as steps involving horizontal and curved portions.

- The instrument used in TGA is a thermobalance.

- TGA gives information only for substances that show a change in mass on heating or cooling.

- The upper temperature used for TGA is normally 1000 °C.

- Quantitative analysis is done from the thermal curve by measuring the loss in mass.

- The data obtained in TGA is useful in determining the purity and composition of materials, drying and ignition temperatures of materials, and knowing the stability temperatures of compounds.

- TGA can be used to evaluate the thermal stability of a material. In the desired temperature range, if a species is thermally stable, there will be no observed mass change. Negligible mass loss corresponds to little or no slope in the TGA trace. TGA also gives the upper use temperature of a material. Beyond this temperature, the material will begin to degrade.

- TGA is used in the analysis of polymers. Polymers usually melt before they decompose, thus TGA is mainly used to investigate the thermal stability of polymers. Most polymers melt or degrade before 200 °C. However, there is a class of thermally stable polymers that are able to withstand temperatures of at least 300 °C in air and 500 °C in inert gases without structural changes or strength loss, which can be analyzed by TGA.

- The simplest materials characterization is the residue remaining after a reaction. For example, a combustion reaction could be tested by loading a sample into a thermogravimetric analyzer under normal conditions. The thermogravimetric analyzer would cause ion combustion in the sample by heating it beyond its ignition temperature. The resultant TGA curve plotted with the y axis as a percentage of initial mass would show the residue at the final point of the curve.

- Oxidative mass losses are the most common observable losses in TGA.

- Studying the resistance to oxidation in copper alloys is very important. For example, NASA (National Aeronautics and Space Administration) is conducting research on advanced copper alloys for their possible use in combustion engines. However, oxidative degradation can occur in these alloys as copper oxides form in atmospheres that are rich in oxygen. Resistance to oxidation is very important because NASA wants to be able to reuse shuttle materials. TGA can be used to study the static oxidation of materials such as these for practical use.

Handled By Er. Atul Singh

atul.singh@iiti.ac.in